Water purification from organics, iron and manganese by non-pressure coagulation

The installation makes it possible to purify water with a content of increased permanganate oxidizability (IPO) of 40 units or higher. Water may contain 15 mg/l of iron, 1.5 mg/I or more of manganese. Also, the installation perfectly cleans turbid water with an odor and high color to the required sanitary standards. In addition, the equipment disinfects water.

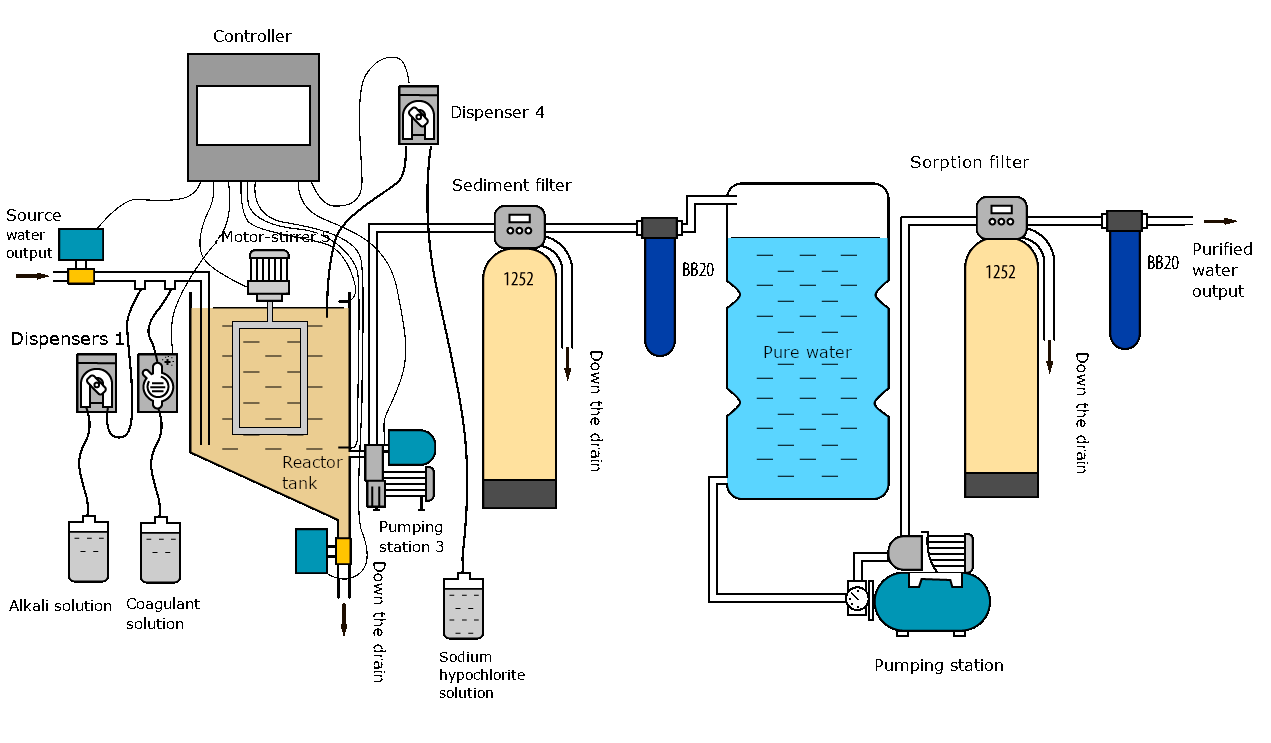

At the command of the controller, an electric ball valve opens and the reactor tank (2) is filled with source water. At the same time, continuous dosing pumps (1) mix working solution of coagulant (for example aqua-aurate) and alkali solution into the source water. After filling the reactor with water, the controller closes the ball valve at the signal of the level sensor. Next, the colloidal substances in the source water react with the coagulant and fall in the form of flakes to the bottom of the reactor tank 2. The dose of coagulant, alkali and sediment settling time are selected experimentally for specific water.

At the end of filling the reactor tank, the agitator motor (5) is switched on for a while to accelerate the coagulation reaction and the formation of sediment flakes.

60-90 minutes after filling the reactor tank, when most of the sediment has fallen to the bottom, the metering pump (4) turns on for a certain time and dispenses a working solution of sodium hypochlorite into water. At the same time, the second mixing of water in the reactor takes place. Sodium hypochlorite oxidizes ferrous iron and manganese, and also disinfects water.

After 2-4 hours, at the end of settling, the controller turns on the pumping station (3) and the clarified water is pumped into the pure water storage tank through sedimentary and cartridge filters. At the end of the pumping cycle from the reactor to the clean water tank, the controller switches off the pumping station (3). The remaining water with sediment at the bottom is drained into the sewer from the reactor tank.

Then the cycle repeats:

1. Filling of the reactor tank with dosing of coagulant and alkali.

2. Dosing of sodium hypochlorite.

3. Sediment settling.

4. Pumping and filtration of clarified water.

5. Draining water with sediment.

Water from the storage tank is supplied to consumers by pumping station (5) morning through sorption and cartridge filters. Activated carbon is necessary to remove chlorine and its compounds from water.

Advantages of this non-pressure coagulation scheme:

- It effectively purifies water with a Significant excess of organic matter, iron and manganese (including high-color peat and swamp waters).

- A significant part of the sediment (coagulated organic matter) simply drains into the sewer and does not enter the filters.

- Full automation of technological processes of water purification is achieved through the use of programmable relay control in the controller. During operation, the programmable relay is easily reconfigured when the quality of the source water changes.

The installation allows you to get up to 2000 liters of clean water per day.